Table of Content

After reading our reviews, you’re probably wondering about what makes one welder better than another. Let’s look at common features of welders that you should consider before making a purchase. Used welders are sometimes available if you know where to look. Pawnshops and other used tool dealers can also have good deals on used welders. Since the settings are pre-programmed, there are some types of stick it can’t handle.

You need protective equipment to keep safe while welding. Dedicated TIG machine with high-end features at a lower price. It doesn’t run AC, so the ability to weld aluminum is limited. No option for AC welding, so the ability to handle aluminum is limited.

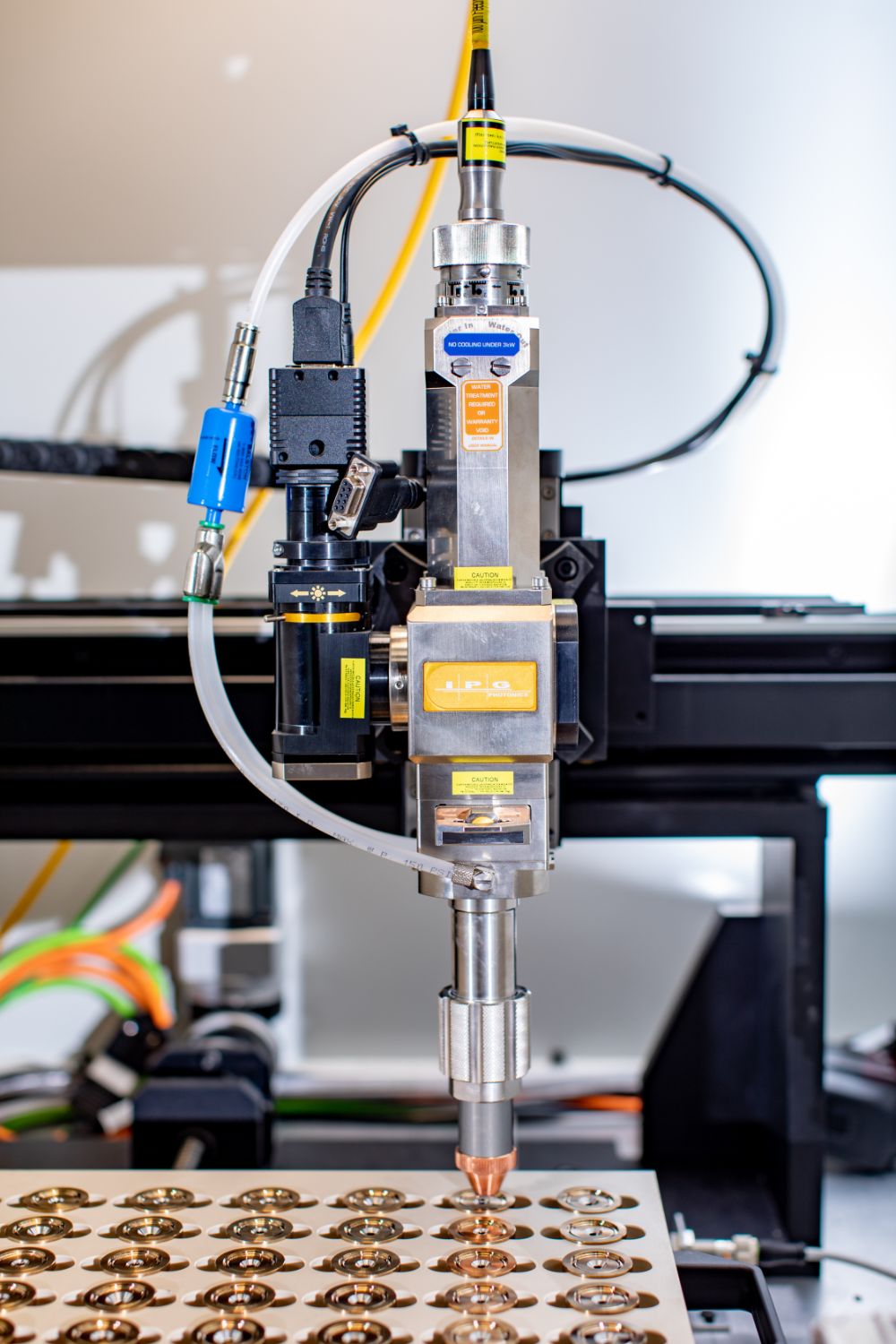

Lotos LTPDC2000D Plasma & TIG Welder

Bench grinders are useful for shaping and cleaning small pieces. They can also be used to sharpen the tungsten electrodes required for TIG welding. Compensation data tools, salary structures, surveys and benchmarks. One positive to this unit is that it is modestly priced. However, the build quality does match the price tag. This product feels a little cheap and DOA units have happened on occasion.

At one of the lowest price points on our list, this welder even includes welding wire and a mask. Of course, the saying that “you get what you pay for” absolutely rings true here. Don’t expect this welder to have plug-and-play functionality like the top welders of this list. This welder has an output range of amps, not nearly as wide as the previous models. Because of this, the Lincoln Handy Core is only capable of welding mild steel up to 1/8” thick. If you’re building anything structural, consider a unit with higher capabilities.

MTS-205 MIG/TIG-Torch/Stick Arc

Cutting torches require oxygen and acetylene, while MIG welders need carbon dioxide or argon. Welding gasses don’t ship well, so that you will need a local source for this. Many metal supply houses also sell welding gasses along with project parts. In addition to the welder, you will need some other equipment to get started welding. Very few homes or general shop tools are adequate for the kind of heavy-duty metalwork that TIG welders needed. If money is no object, or you will be welding all day, every day, go for the big Precision TIG 225 from Lincoln Electric.

While it is advertised as a MIG welder, in reality, it’s a flux core wire welder and does not offer true MIG welding. The wire feed speed is inconsistent, making it extremely difficult to get a clean bead. When you’re first starting out, this will only make learning welding more frustrating. This product often arrives broken, and there is only a three-month warranty.

Inverter TIG Welder

Never look at a welding arc without shielding your eyes. Using a mask rather than goggles protects the skin of your face from heat and sparks, as well. Auto-darkening masks let you see through the mask, then darken when you crack an arc.

This is another weld-it-all machine like the Miller, but at a better price. This welder is best for someone who welds a wide variety of projects but isn’t a pro. You can do anything with it, but it probably won’t run every day for years like expensive welders will. The package comes with TIG torch, stick clamp, plasma torch, air regulator for a plasma cutter, and argon regulator.

Of course, having two different welders can get unwieldy to move around and store. Combining both TIG and stick-type welding into one unit means you don’t have to pick between the two. It isn’t that hard, but it requires some practice to get the perfect “stack of dimes” appearance for the bead. One way to practice is to get a small metal plate and run bead after bead across the surface. A better way to practice TIG welding is to make shop projects. You are going to need a metal cutter to be a welder, so you might as well get one combined with the welder.

Land an apprenticeship and earn while you learn from experienced welders. You can even get fancy and build a shielded welding table. A table with walls on three sides will let you TIG weld outside without the wind interfering. Being able to work outside opens up some new opportunities for you as a welder.

Angle grinders do the same work as bench grinders, but you can carry the angle grinder around. They help clean surfaces on big pieces before welding. Angle grinders can also be pressed into service to do some cutting. If you are doing much welding, you will probably want some kind of power tool to cut and shape metal. With temperatures approaching 6000 °, welding produces conditions that are harmful to the body.

Overall, this machine doesn’t inspire much confidence. A metal welding table is an excellent way to set up your workpiece and make sure it’s connected back to the welder. You attach the return lead from the welder to the table, then put your workpiece on the table and start welding. If you don’t already have one, a metal welding table should be one of your first welding projects. The Hitbox 200 amp dual-volt TIG welder is a great entry-level machine.

Lincoln Electric has a reputation for making great welders, and this is no exception. It has the amperage and duty cycle to weld anything you can get into your shop, and the price to match. This is the welder for someone who wants to TIG weld all day, every day, and can make that pay.

MIG welding works well indoors and is a great choice when welding in the garage. The welds produced by stick welding are not the most beautiful. There is a great deal of spatter, and they will require cleanup.